AppRecs review analysis

AppRecs rating 4.5. Trustworthiness 76 out of 100. Review manipulation risk 20 out of 100. Based on a review sample analyzed.

★★★★☆

4.5

AppRecs Rating

Ratings breakdown

5 star

71%

4 star

7%

3 star

7%

2 star

0%

1 star

14%

What to know

✓

Low review manipulation risk

20% review manipulation risk

✓

Credible reviews

76% trustworthiness score from analyzed reviews

✓

High user satisfaction

79% of sampled ratings are 4+ stars (4.2★ average)

About CNC Lathe Simulator

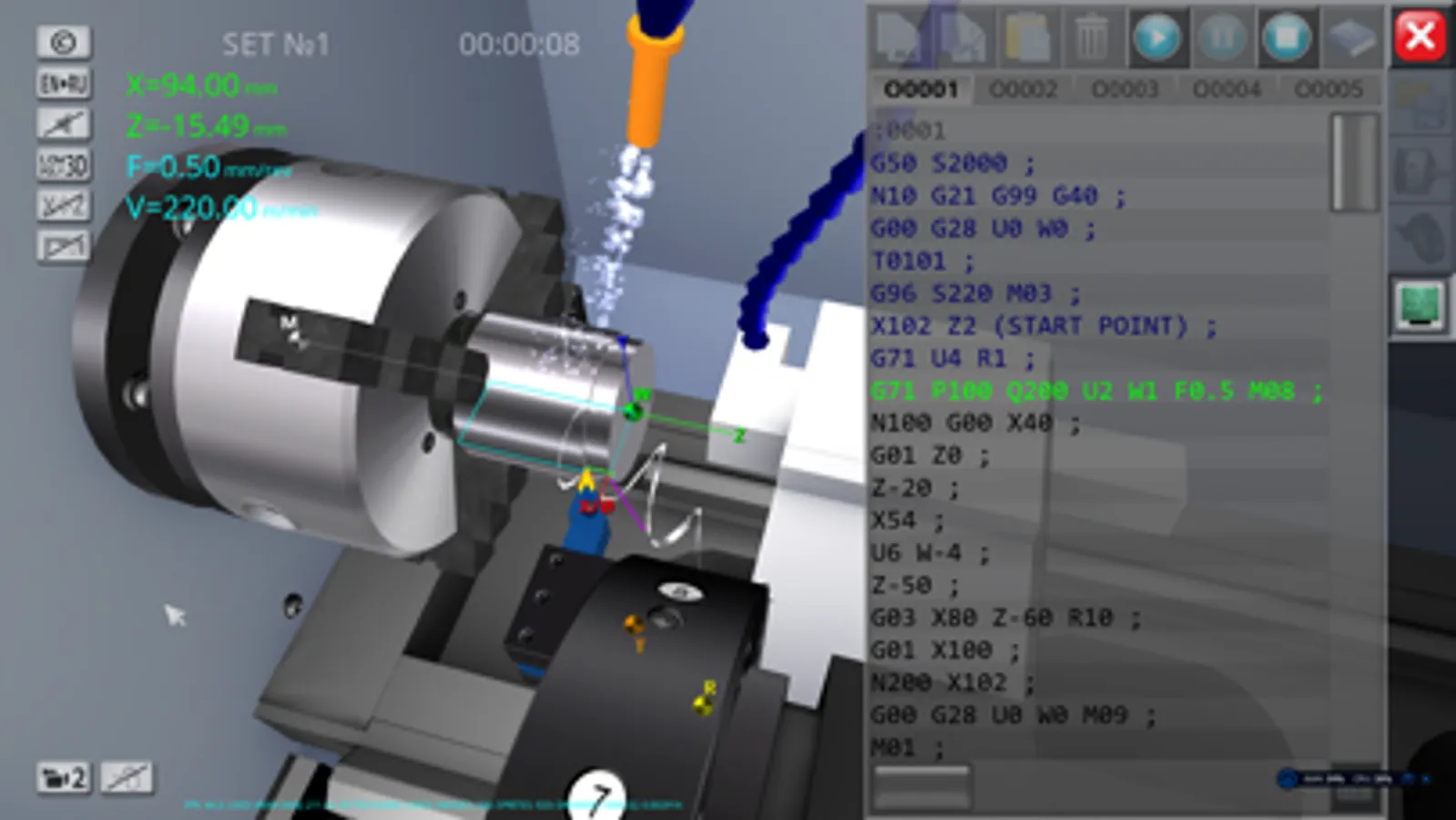

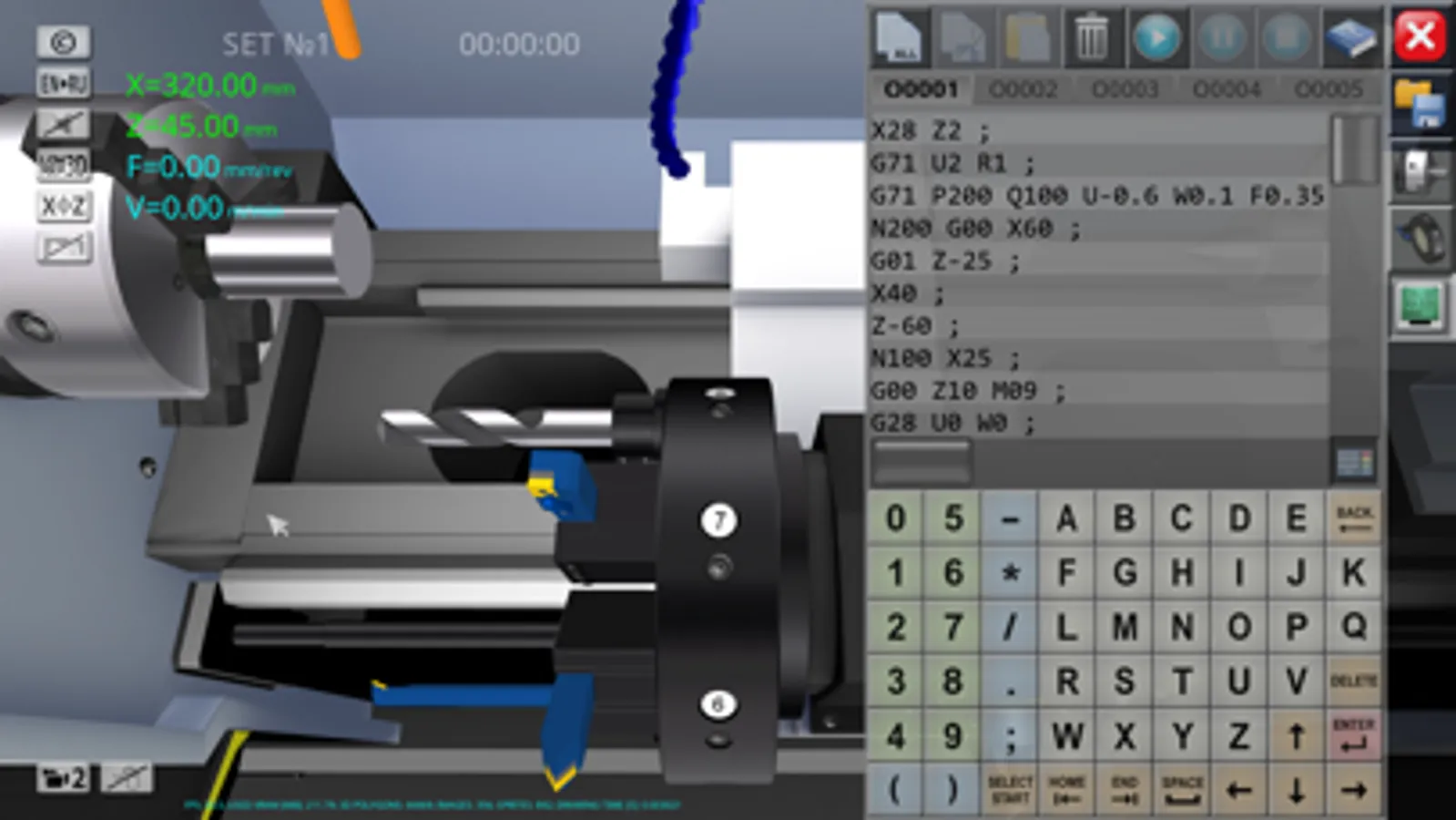

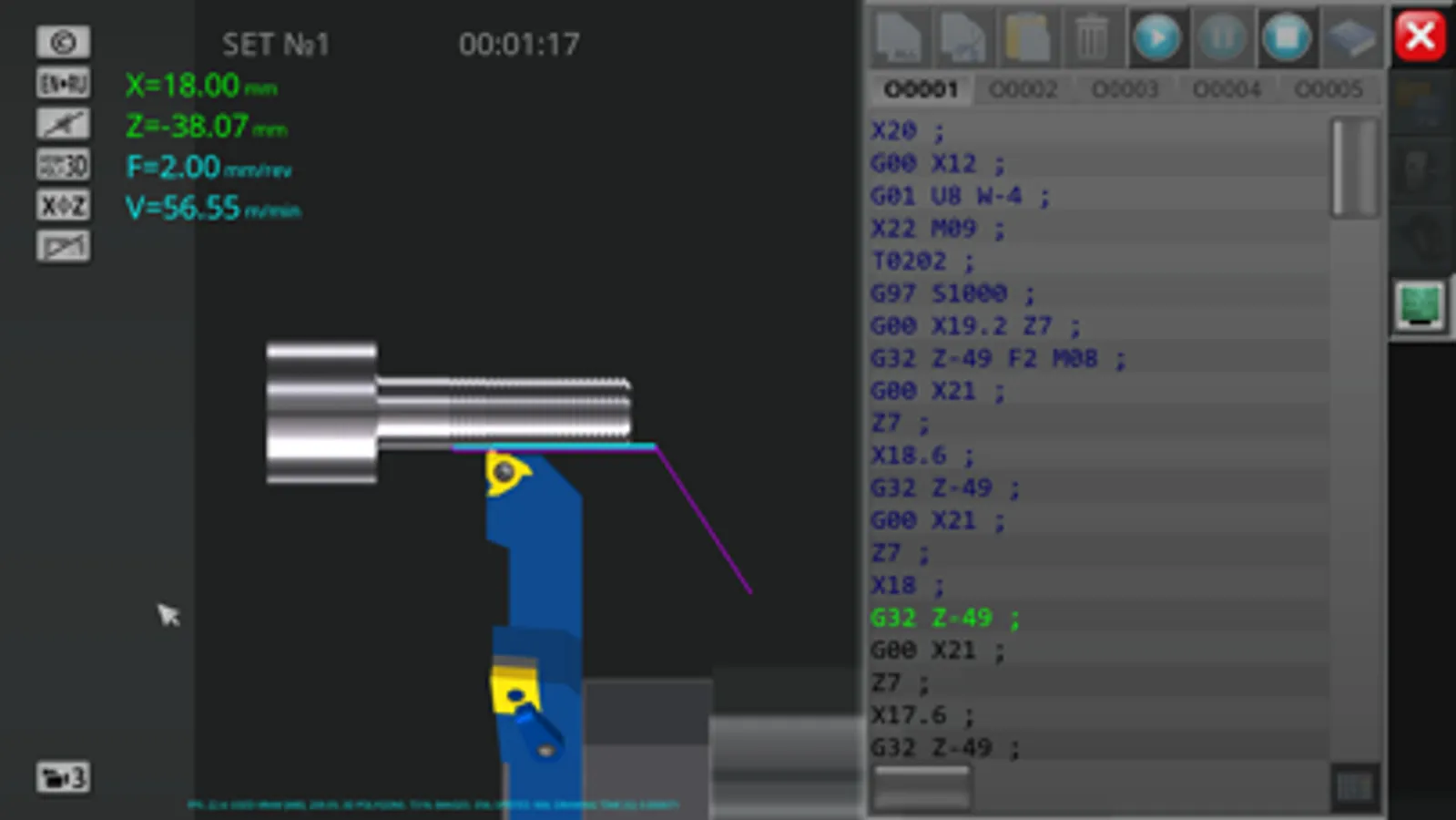

CNC Lathe Simulator is a software simulator of a numerical control lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard G-code (ISO).

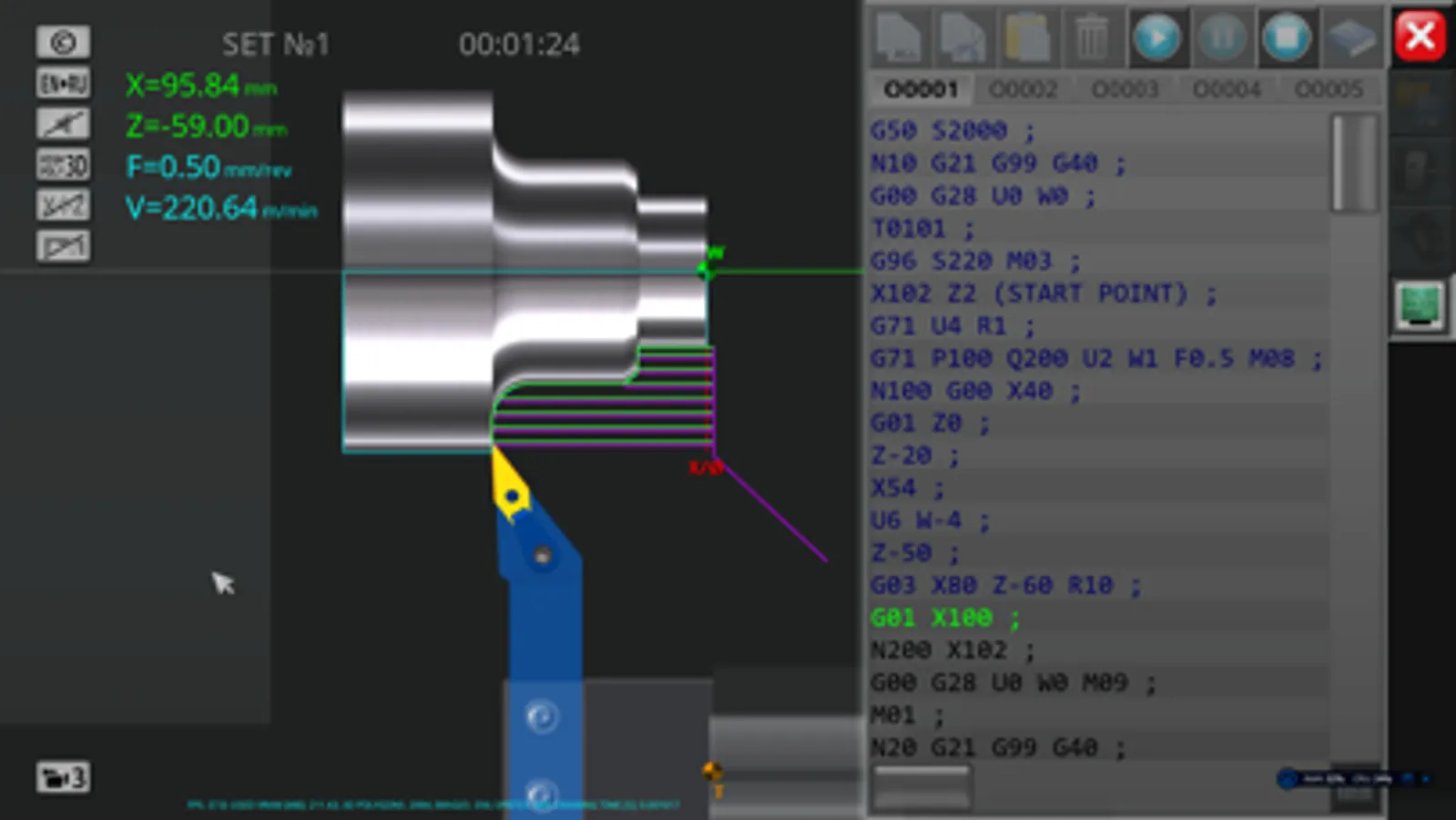

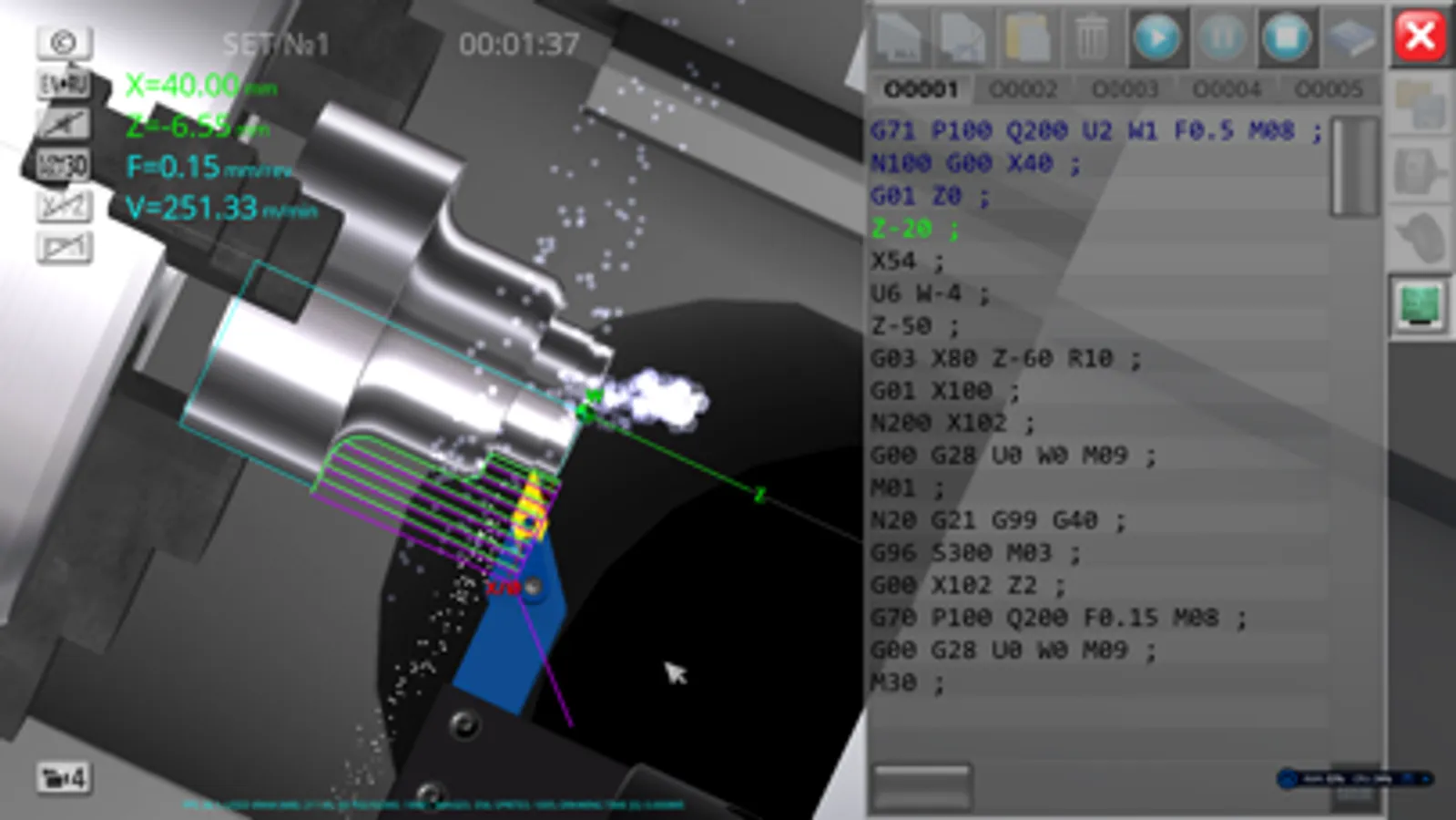

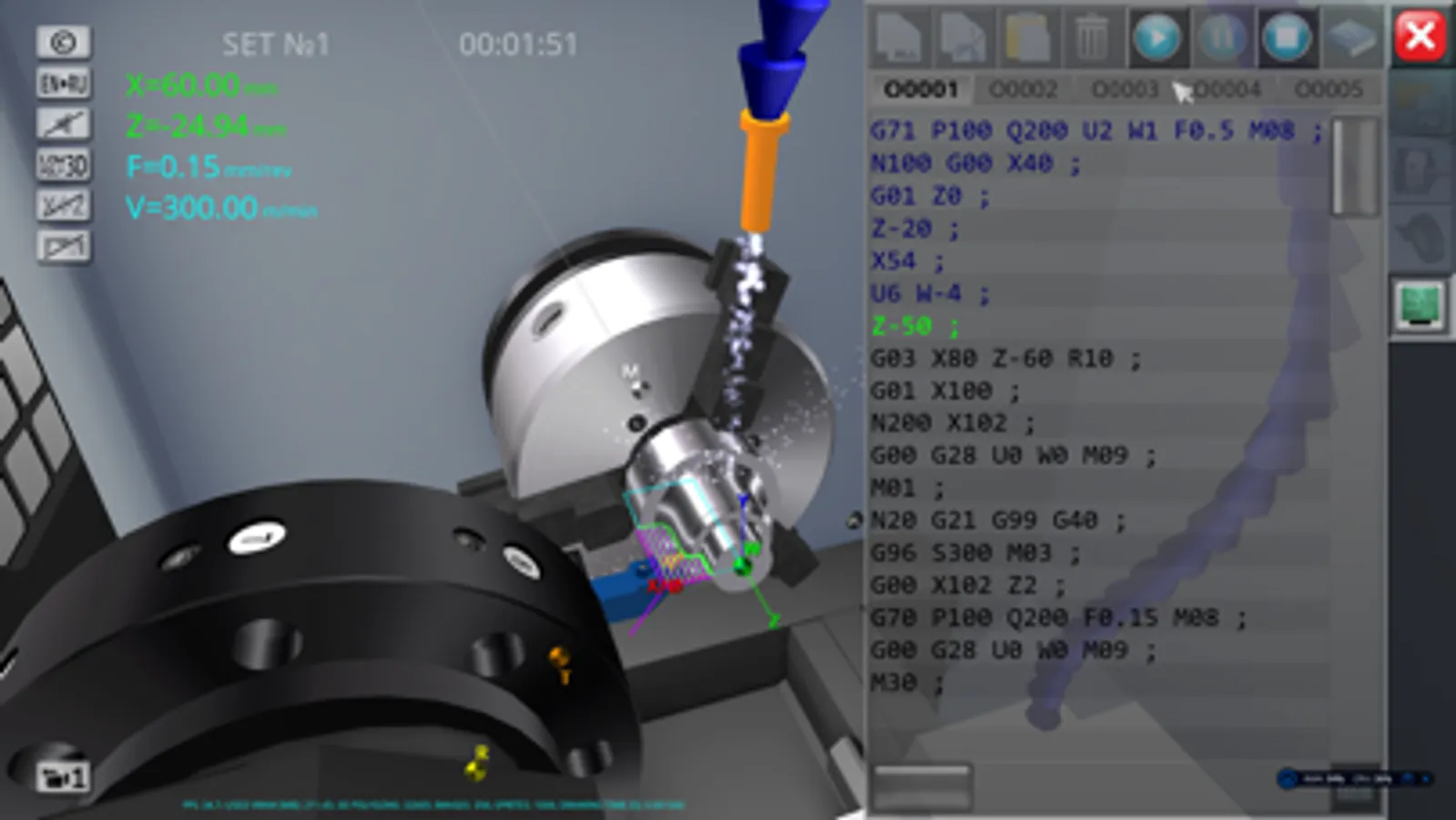

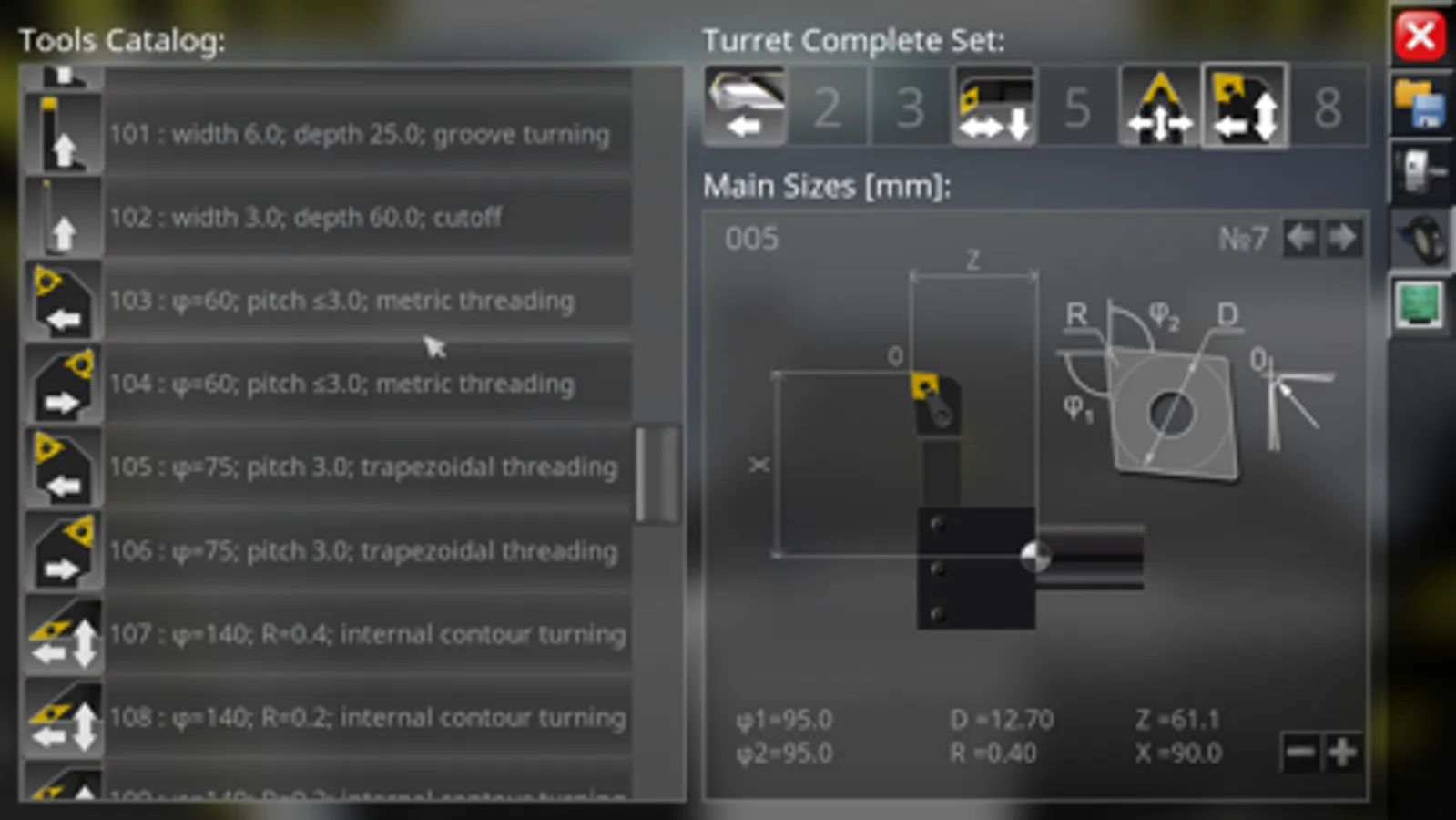

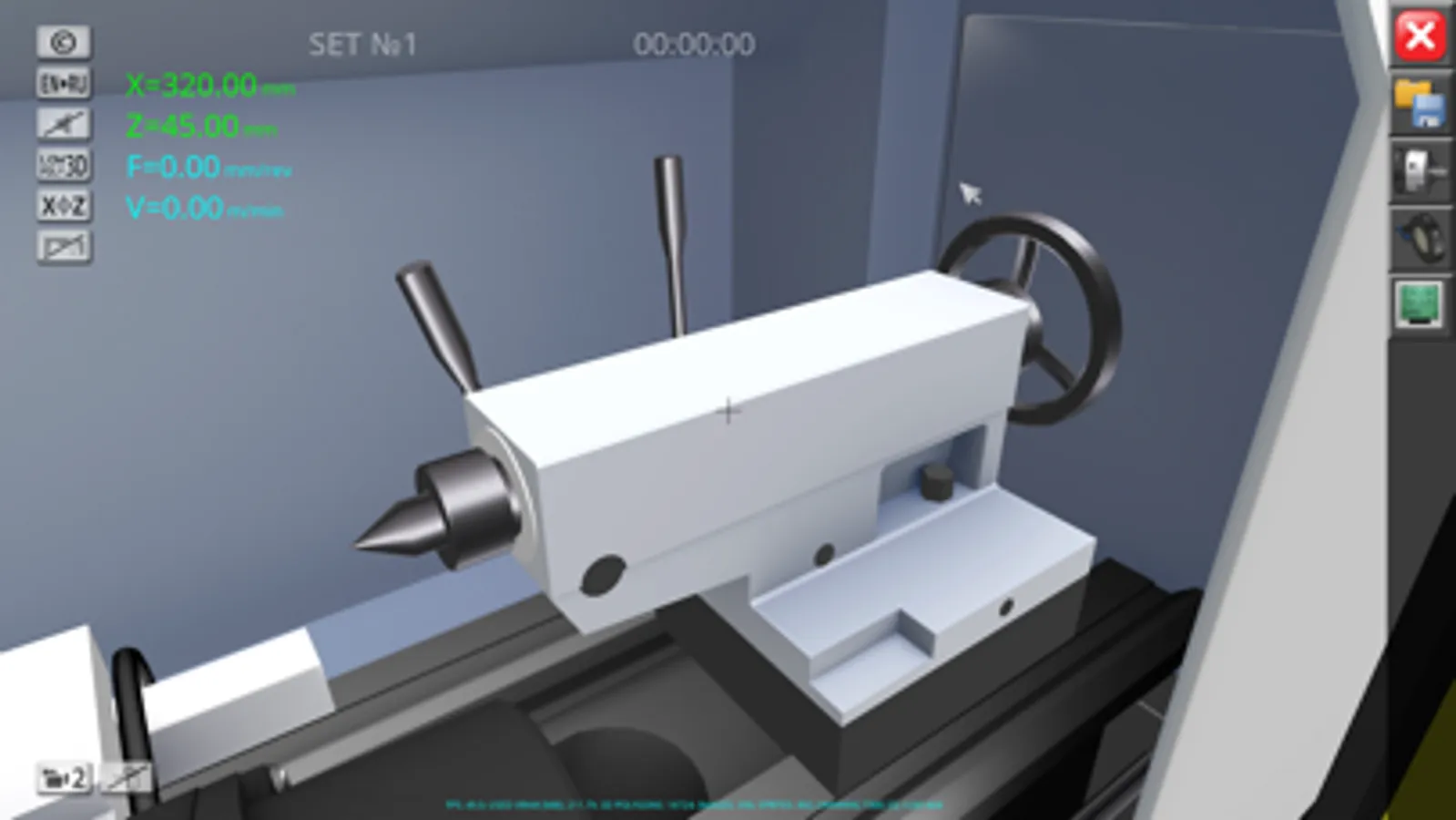

The three-dimensional simulation model is based on a lathe with an inclined bed, equipped with a CNC system, a twelve-position turret head, a three-jaw chuck, a tailstock, a system for supplying lubricating and cooling liquid, and other units. The material is processed along two controlled axes.

Field of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing».

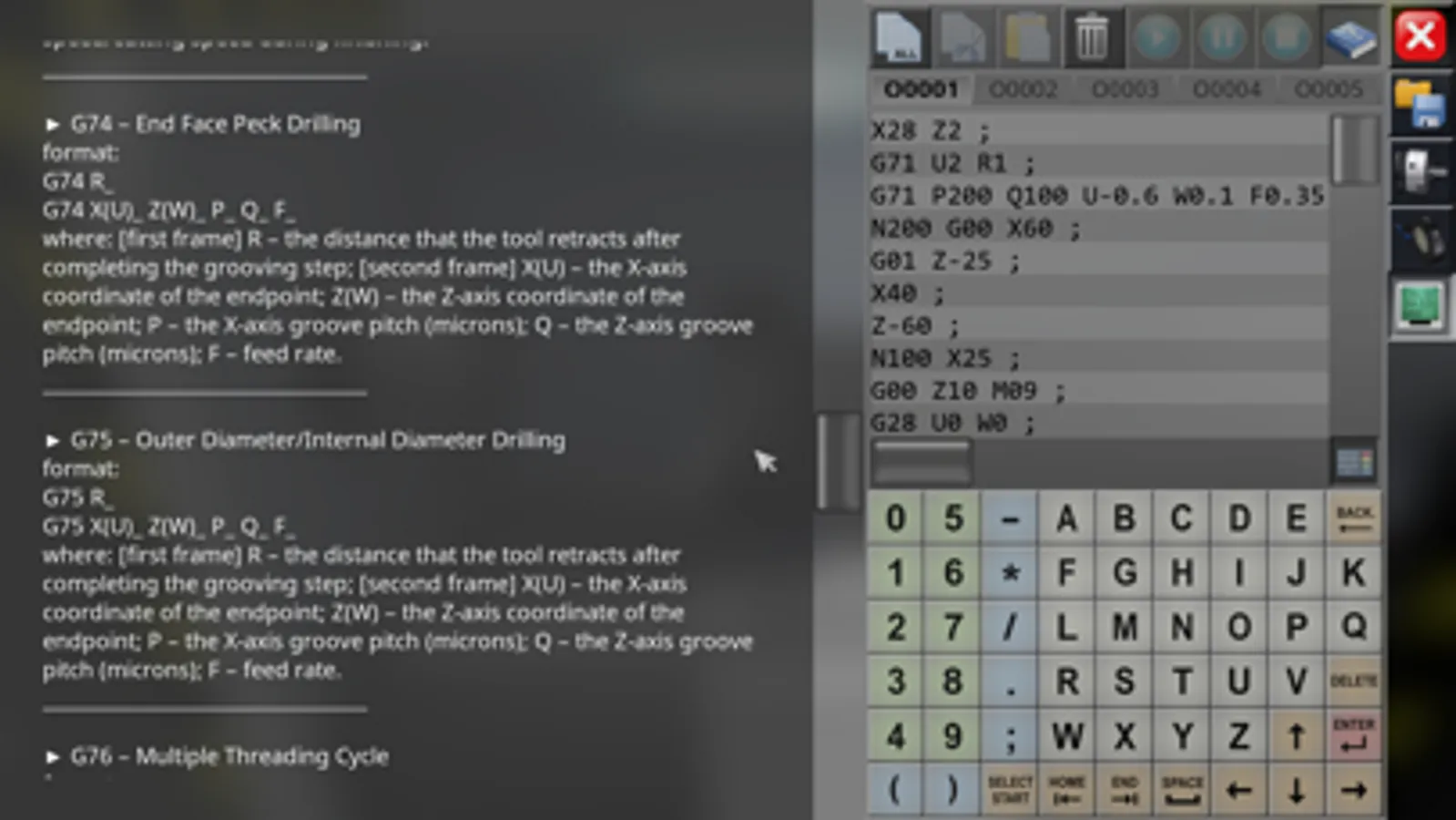

The main functions of the application: editing the code of control programs of a lathe, operations with control program files, setting up geometric parameters of a cutting tool, continuous/step-by-step execution of control program blocks, three-dimensional visualization of tool movements in the machine’s workspace, simplified visualization of the workpiece surface, calculation of processing modes, a brief reference guide on using G-code.

The graphics component of the software uses the OpenGL 2.0 component base. The graphical user interface of the program is implemented in English.

The three-dimensional simulation model is based on a lathe with an inclined bed, equipped with a CNC system, a twelve-position turret head, a three-jaw chuck, a tailstock, a system for supplying lubricating and cooling liquid, and other units. The material is processed along two controlled axes.

Field of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing».

The main functions of the application: editing the code of control programs of a lathe, operations with control program files, setting up geometric parameters of a cutting tool, continuous/step-by-step execution of control program blocks, three-dimensional visualization of tool movements in the machine’s workspace, simplified visualization of the workpiece surface, calculation of processing modes, a brief reference guide on using G-code.

The graphics component of the software uses the OpenGL 2.0 component base. The graphical user interface of the program is implemented in English.