AppRecs review analysis

AppRecs rating 3.2. Trustworthiness 79 out of 100. Review manipulation risk 24 out of 100. Based on a review sample analyzed.

★★★☆☆

3.2

AppRecs Rating

Ratings breakdown

5 star

29%

4 star

43%

3 star

0%

2 star

0%

1 star

29%

What to know

✓

Low review manipulation risk

24% review manipulation risk

✓

Credible reviews

79% trustworthiness score from analyzed reviews

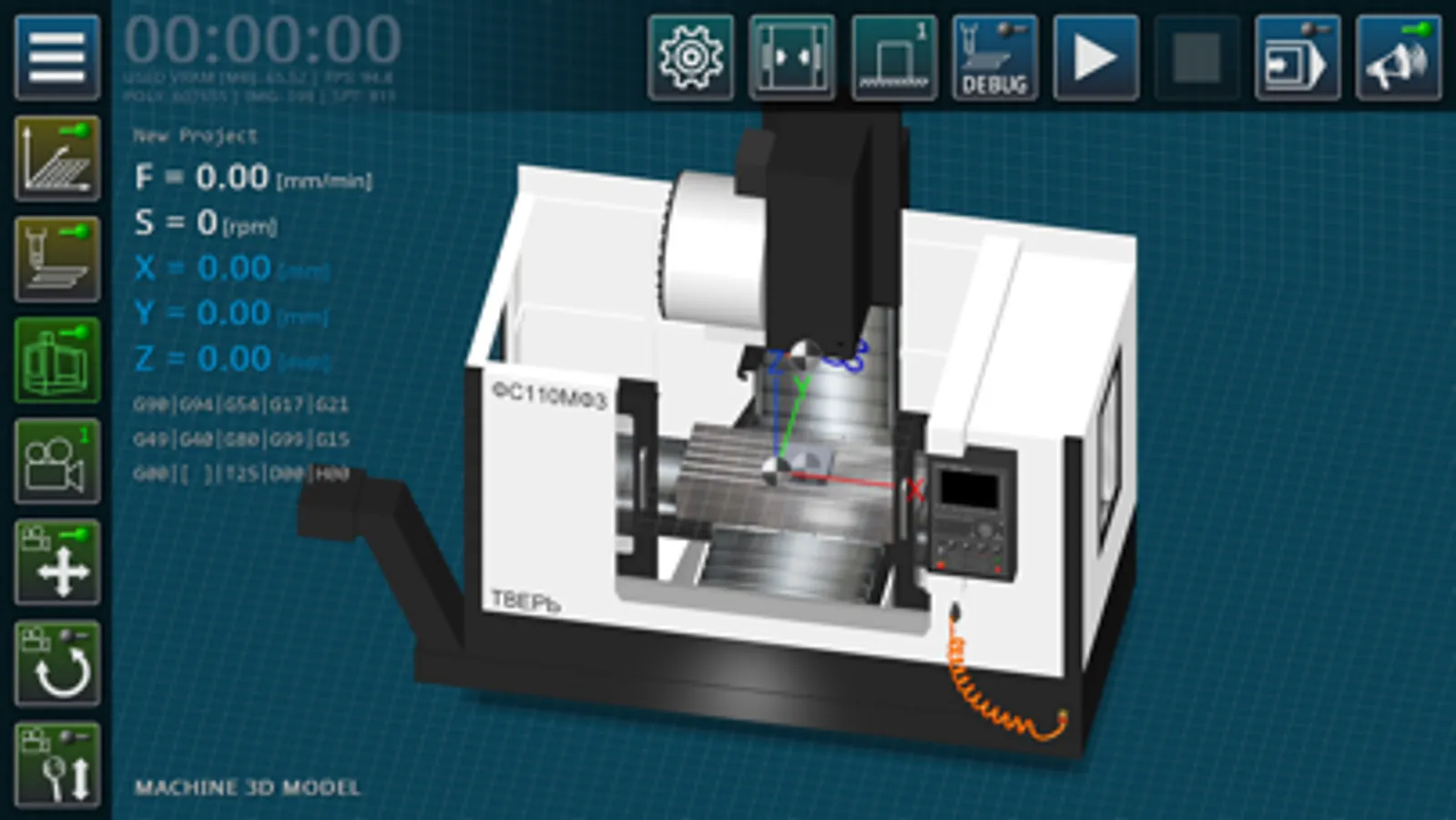

About CNC VMC Simulator

The CNC milling machine simulator is a multimedia application designed to provide a basic introduction to beginner mechanical engineering professionals with the principles of programming operations for milling parts using a standard (ISO) G-code.

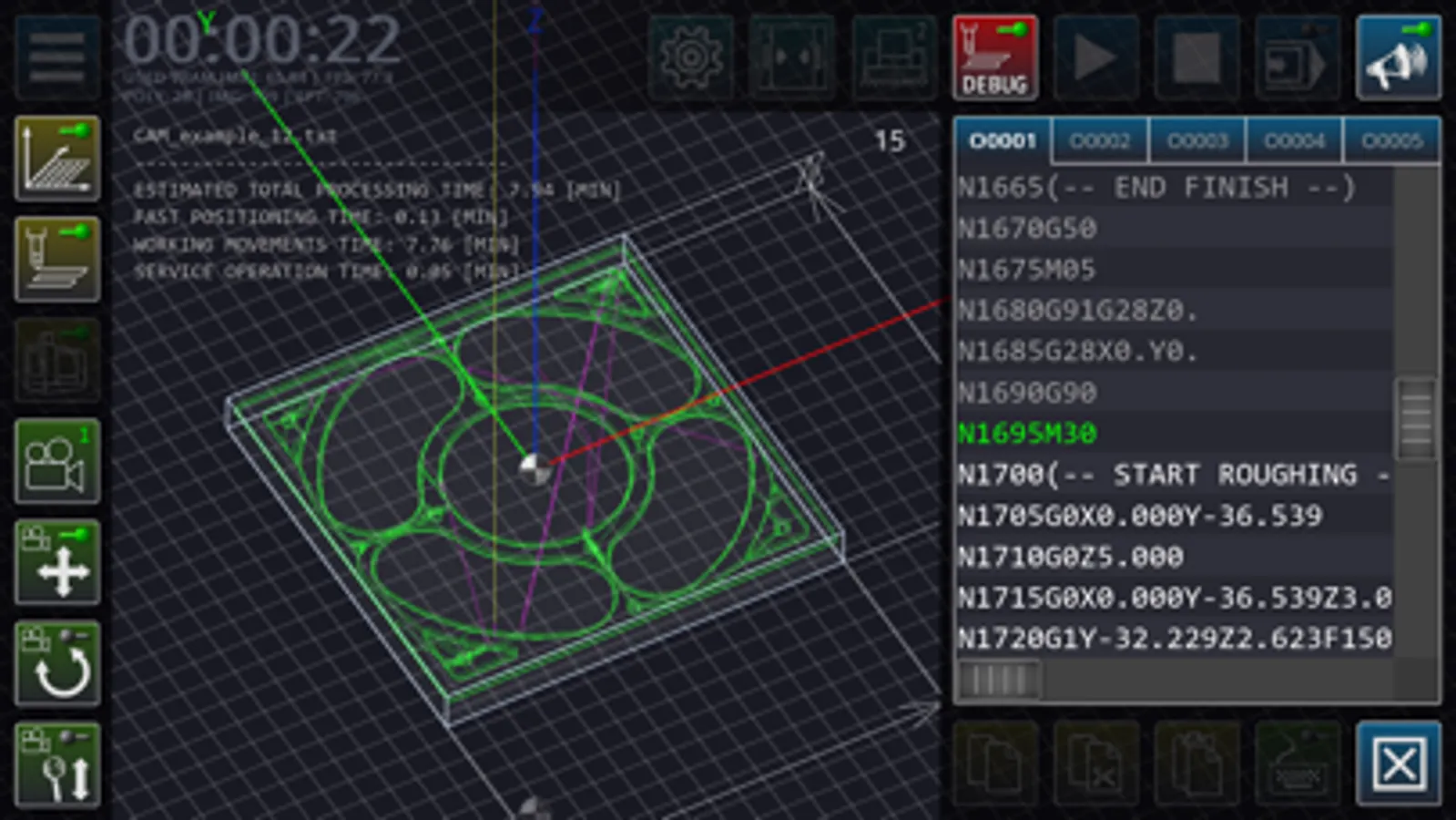

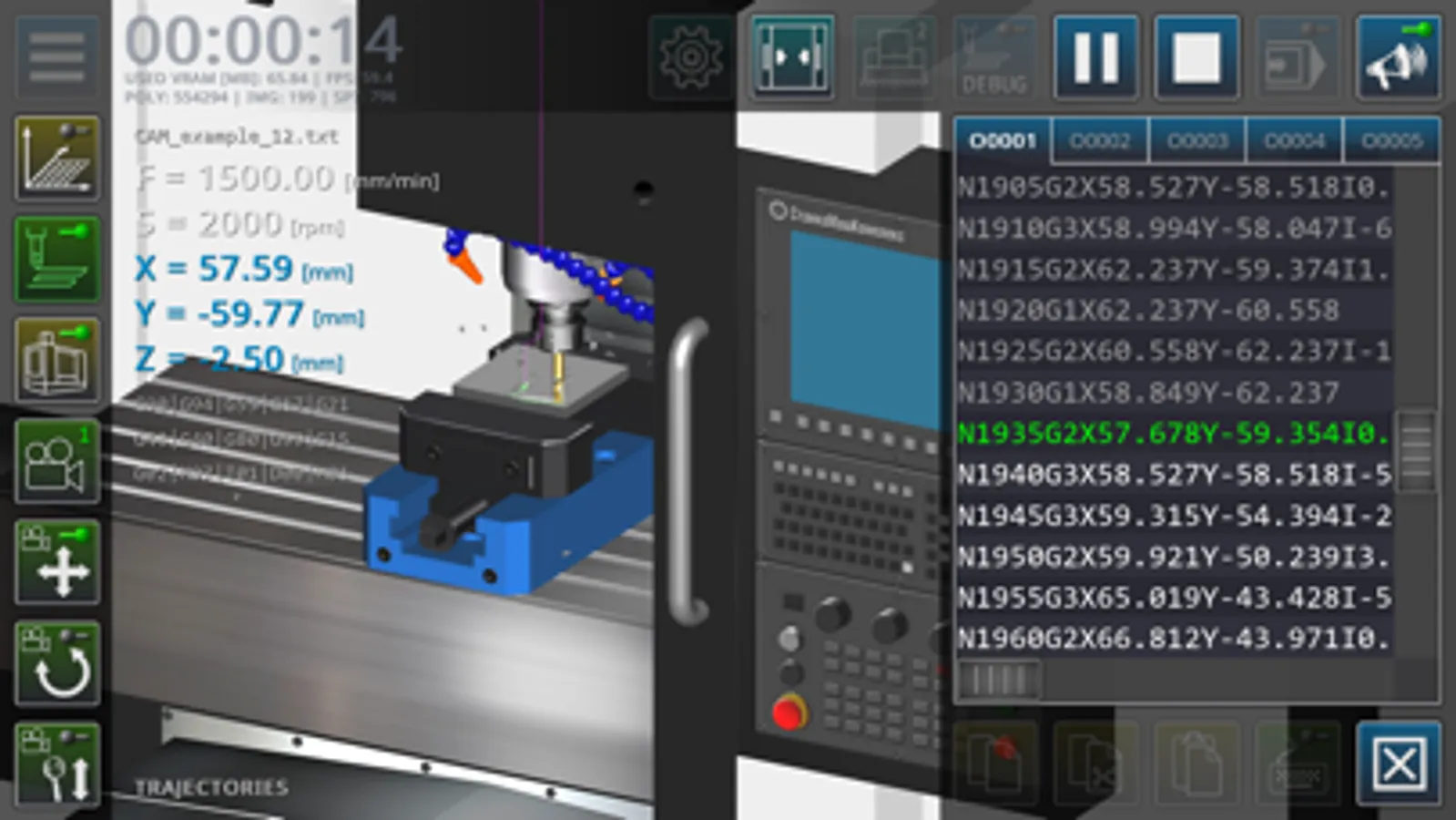

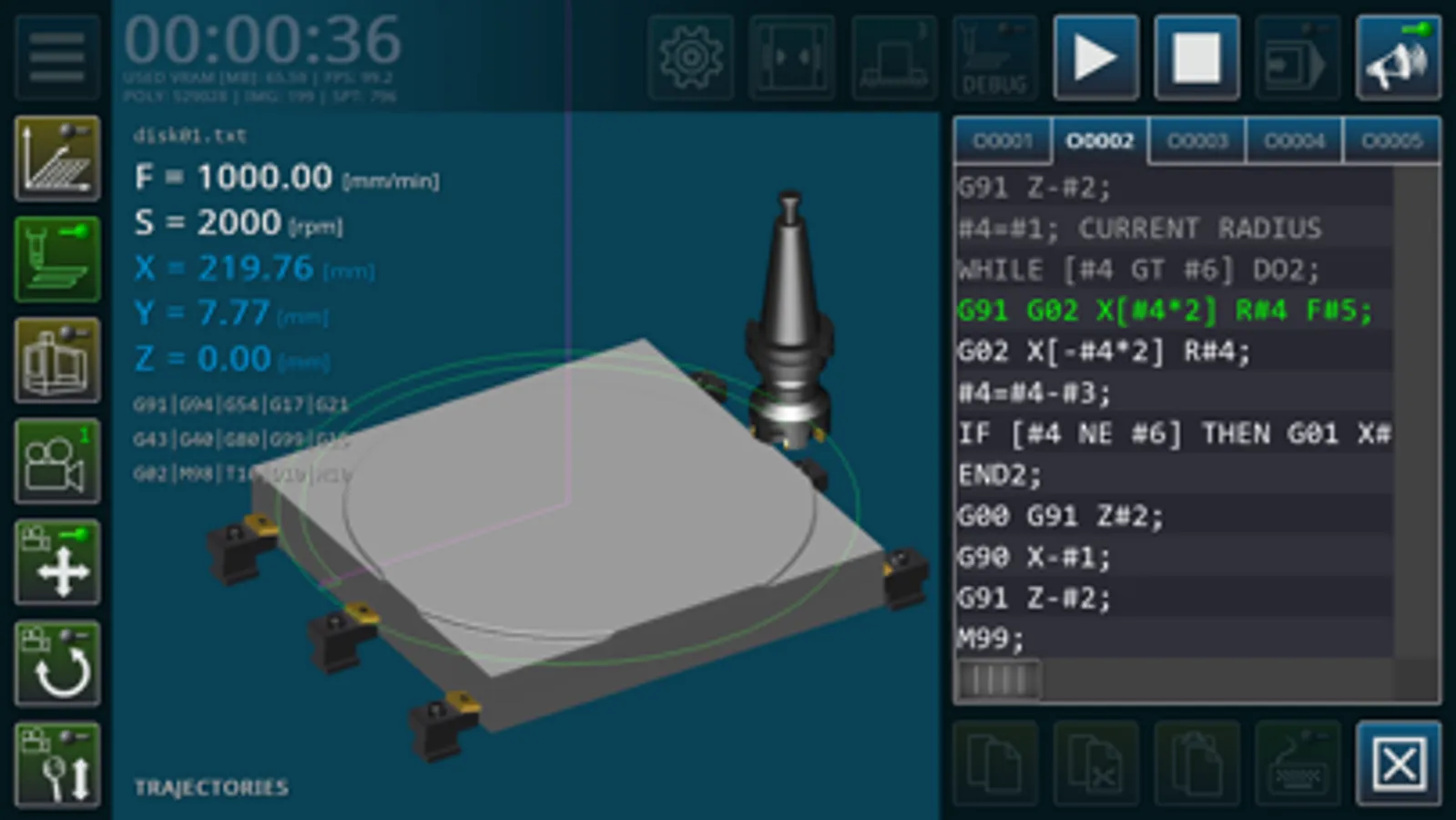

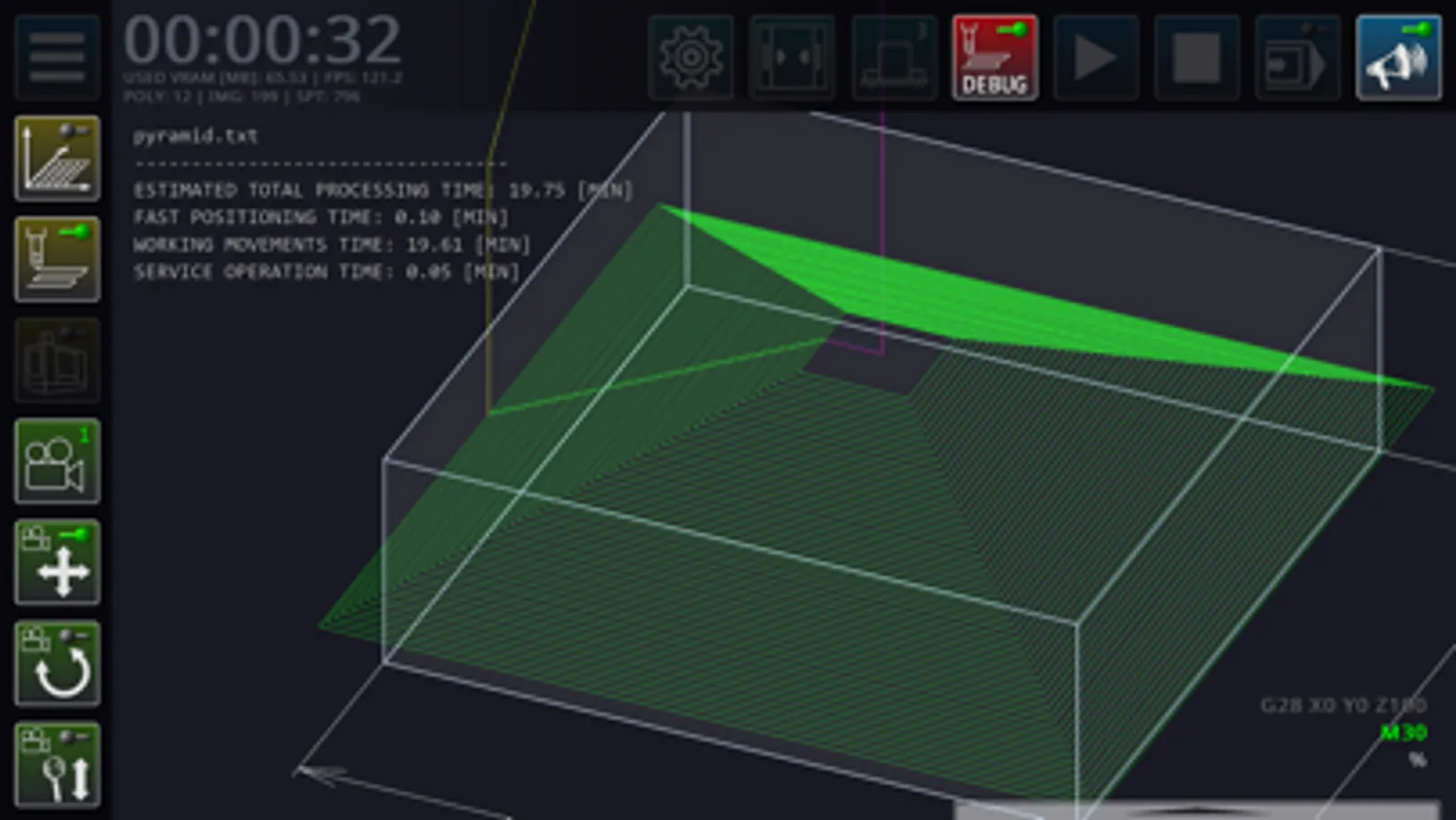

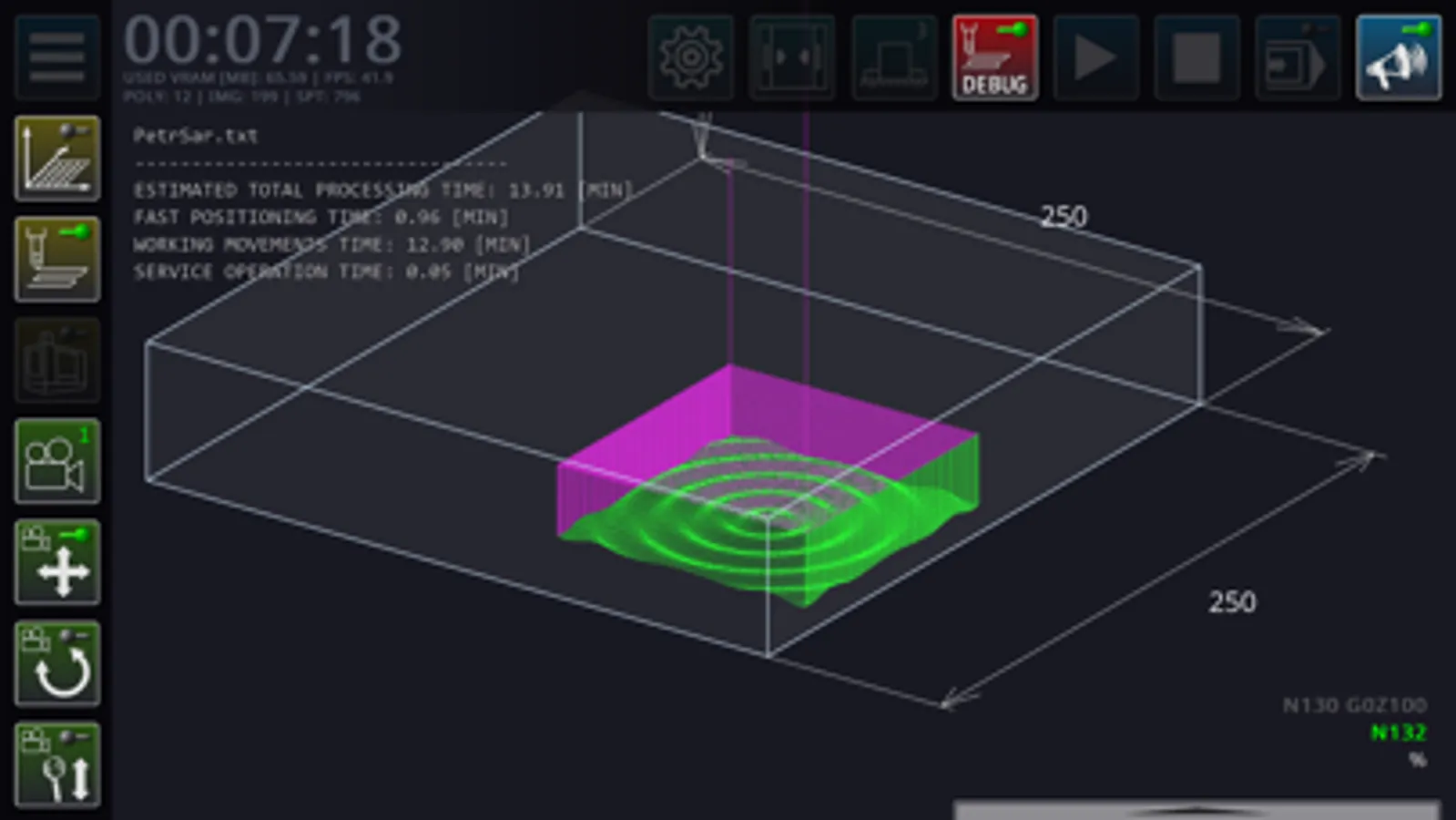

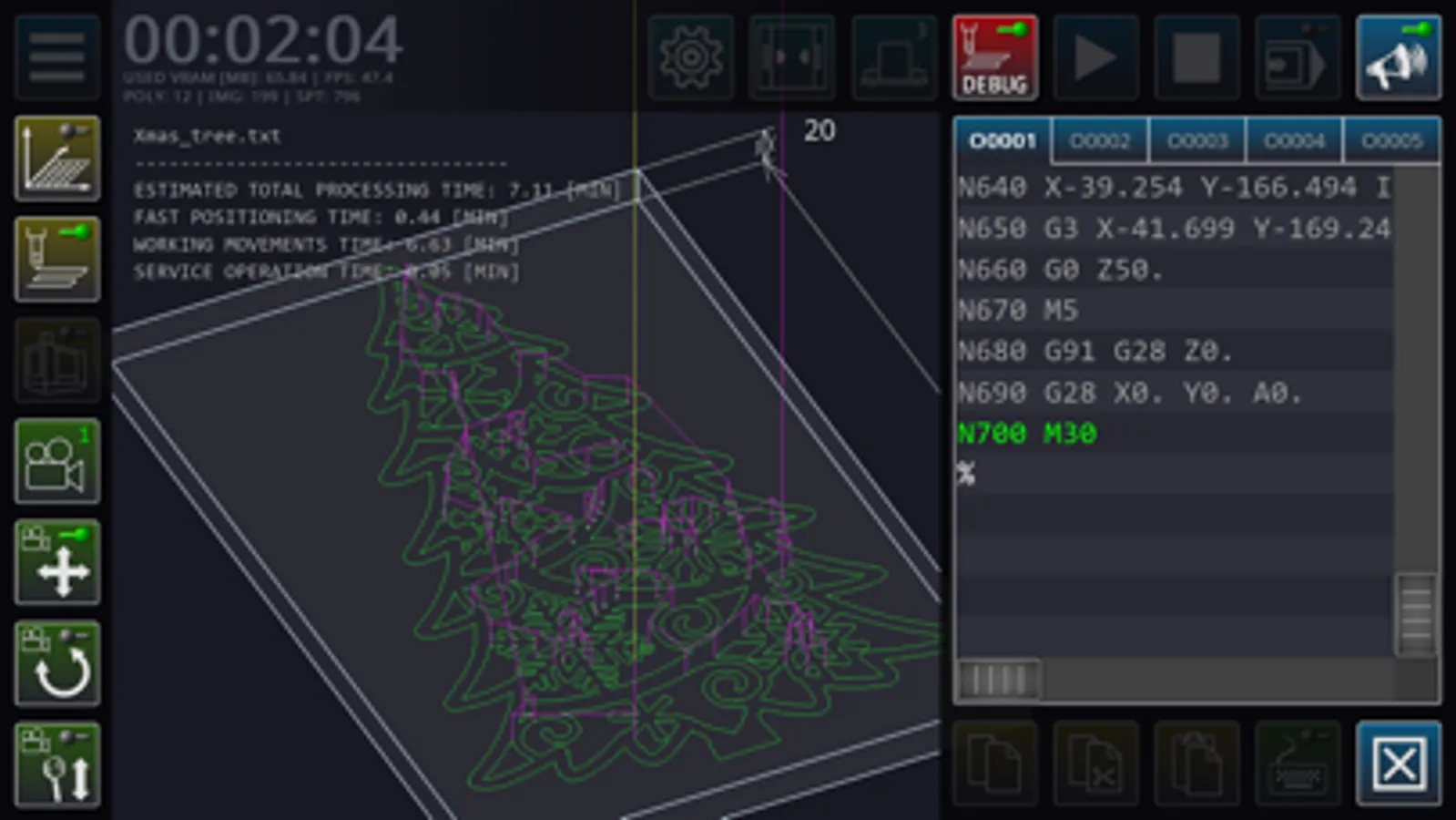

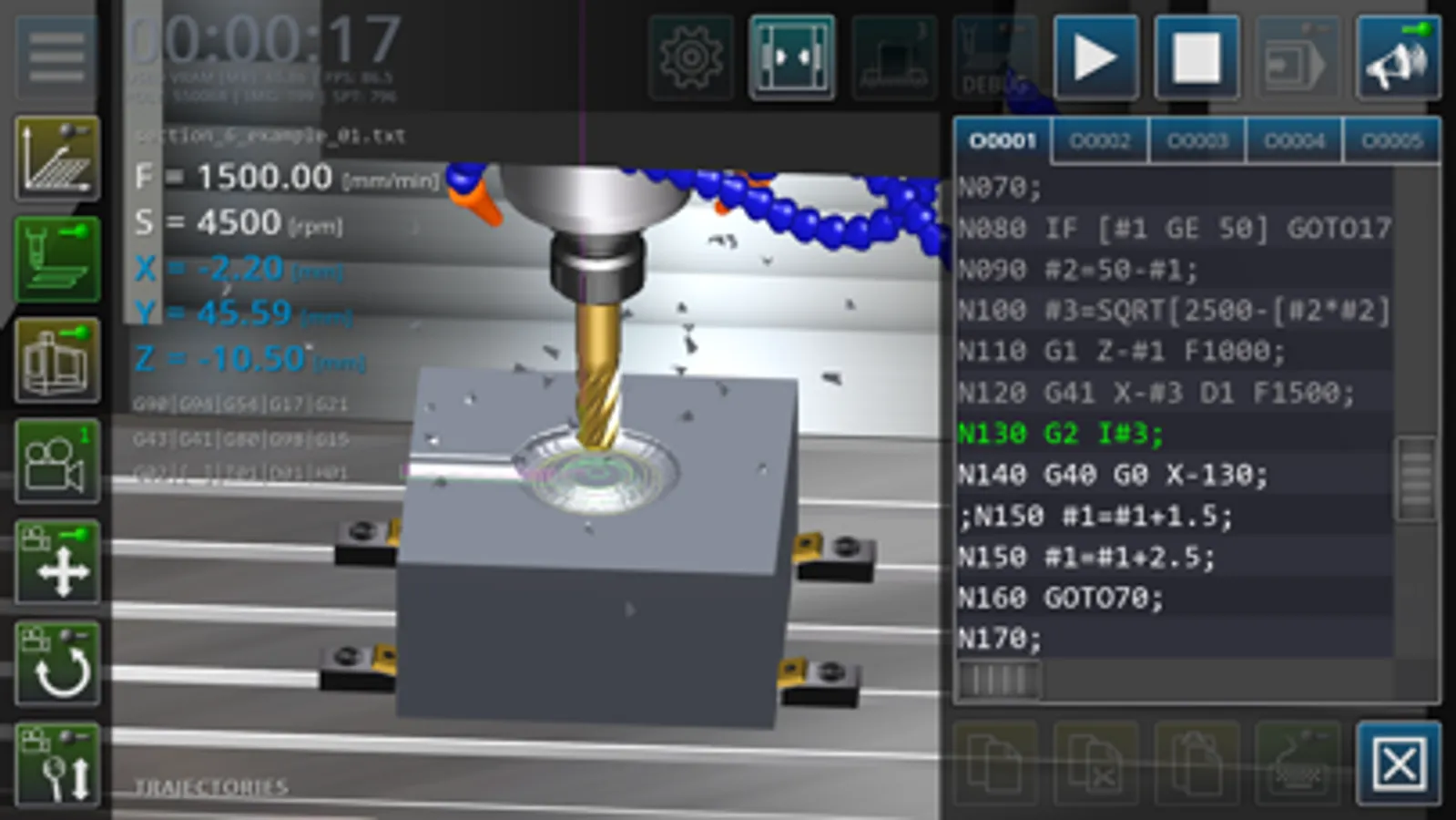

The main task of the application is syntactic analysis (parsing) of the code of control programs in order to build a graphical model of cutting tool trajectories in three-dimensional space.

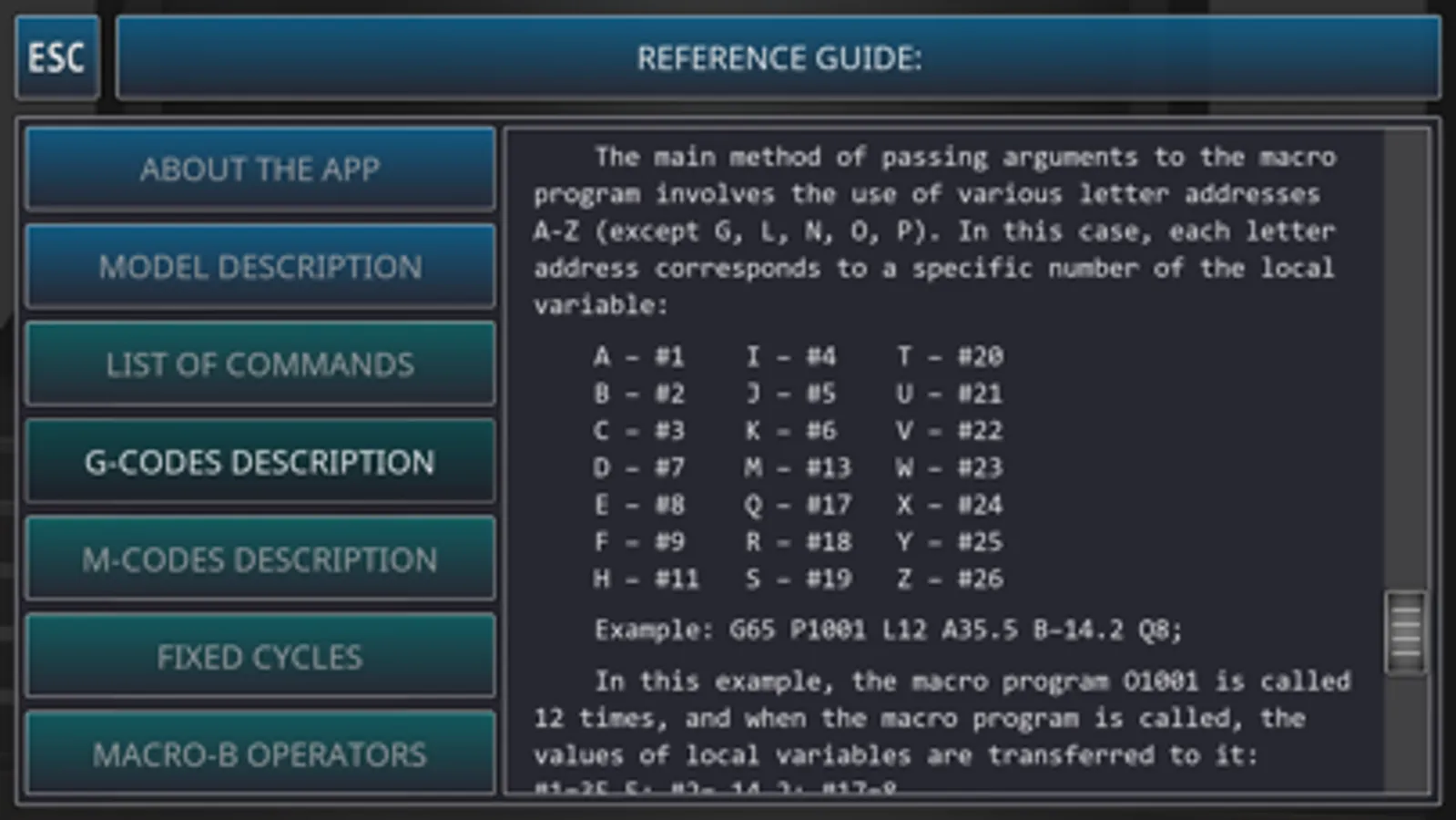

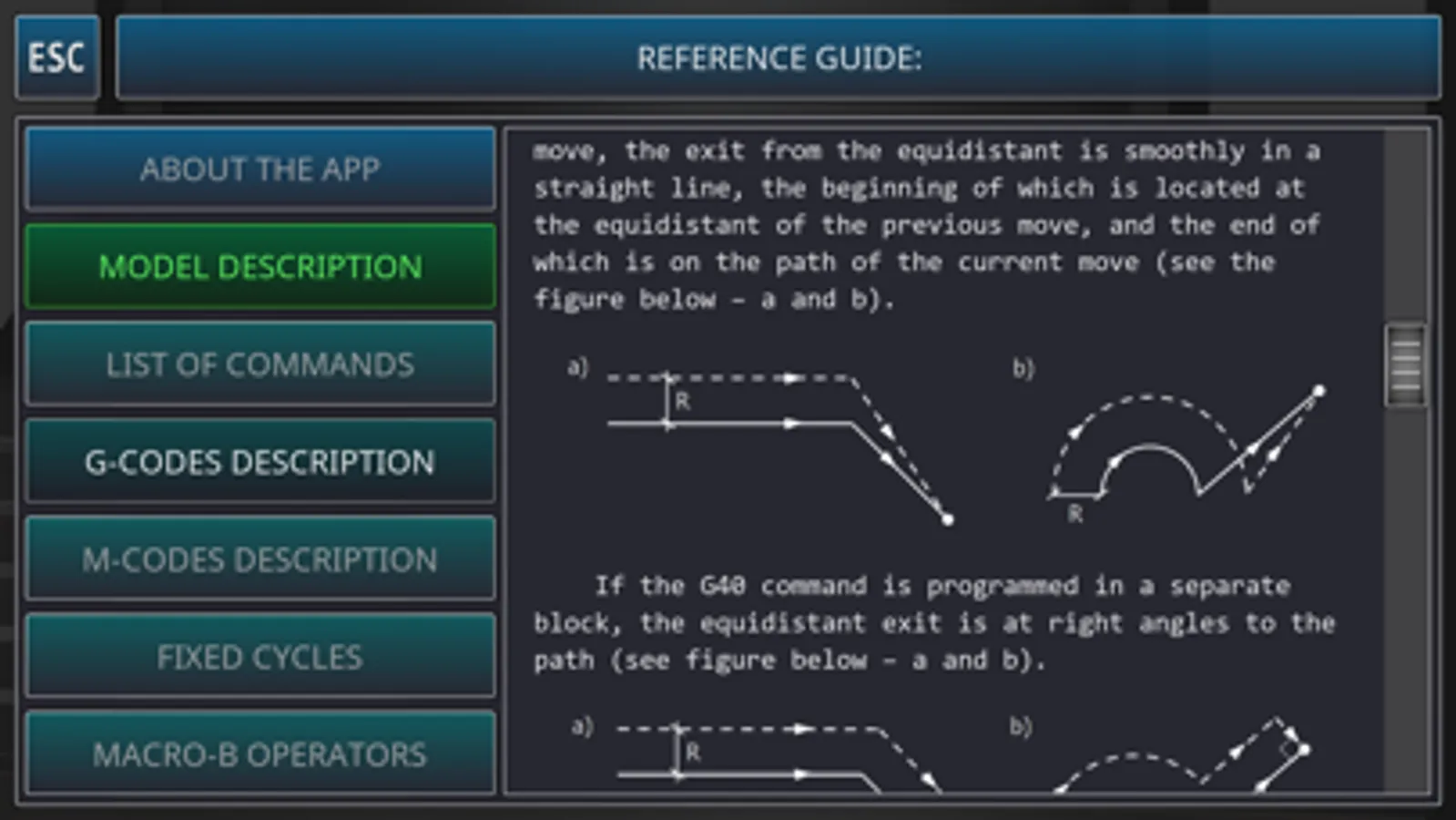

The main functions of the application: editing the code of the control programs of the milling machine, operations with files of control programs, setting the geometric parameters of the cutting tool, continuous/step-by-step execution of blocks of control programs, three-dimensional visualization of tool movements in the working space of the machine, simplified visualization of the machined surface of the part, calculation of processing modes, a quick reference guide to using G-code.

The main limitations of the application are: low accuracy of cutting surface modeling, the impossibility of using polygonal geometry as a workpiece, a simplified model of machine tooling elements.

The main task of the application is syntactic analysis (parsing) of the code of control programs in order to build a graphical model of cutting tool trajectories in three-dimensional space.

The main functions of the application: editing the code of the control programs of the milling machine, operations with files of control programs, setting the geometric parameters of the cutting tool, continuous/step-by-step execution of blocks of control programs, three-dimensional visualization of tool movements in the working space of the machine, simplified visualization of the machined surface of the part, calculation of processing modes, a quick reference guide to using G-code.

The main limitations of the application are: low accuracy of cutting surface modeling, the impossibility of using polygonal geometry as a workpiece, a simplified model of machine tooling elements.